The FDA’s guidelines for cleaning validation call for corporations to properly demonstrate that a cleaning method can regularly clean up products to a predetermined common.

Compounding pharmacists Participate in a vital position in Health care settings, These are specialized from the compounding of medicines and guaranteeing their Risk-free and productive use within the Neighborhood.

7.1 Detergents should really aid the cleaning approach and be easily detachable. Detergents which have persistent residues such as cationic detergents which adhere really strongly to glass and so are tricky to remove, really should be averted where doable.

If related equipment is employed continuously in a chain, surface region to be regarded for each time of use in the course of the calculation of the entire surface area spot.

MACO and NOEL Calculation are greatly employed for figuring out acceptance requirements, cleaning concentrations, Resolve of the level of residue current, and cleaning validation protocol.

A well-liked academic website for pharmacy learners, pharmacy specialists and pharmaceutical experts.

eight.five Control of the bioburden by way of enough cleaning and suitable storage of kit is very important to make certain subsequent sterilization or sanitization procedures attain the required assurance of sterility, along with the control of pyrogens in sterile processing.

Risk assessment: A thorough threat evaluation from the procedures for use for cleaning the equipment ought to be executed. A threat-dependent strategy should be followed when setting up a cleaning validation protocol.

Cleaning validation plays a vital position in cutting down the potential for product contamination from pharmaceutical manufacturing equipment.

Shifting cleaning treatments: Any adjustments in cleaning treatments, the cleaning agent employed & other methods demand cleaning validation.

Deciding on and screening beneath worst-scenario circumstances guarantees the cleaning course of action is effective below all probable circumstances. This approach is pivotal for guaranteeing client protection and solution high-quality.

To display for the duration of validation that the cleaning technique, routinely employed for a bit of kit, limits check here opportunity carryover to a suitable degree.

Evidently define what, who, how, and when to accomplish Each and every cleaning move. A complete and precise description of each phase of your cleaning protocol needs to be a Element of the validation process.

Sartorius continues cleaning validation calculation to be a pacesetter in the field of extractables and leachables due to the fact 1996, which implies we convey deep understanding of the science of extractables to each venture.

Mara Wilson Then & Now!

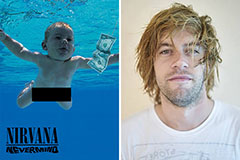

Mara Wilson Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now!